- Colour: Clear

- Specials*: Special transparent, translucent and opaque options are available on request

- Options: Coating on one side only to allow reverse printing, available in Marlon BioPlus

| Sheet size (mm) | Thickness (mm) |

|---|---|

| 2000 x 3000 | 2, 3, 4, 5, 6, 8, 10 & 12 |

*Other thicknesses available on request. Minimum order quantities may apply. Please contact Brett Martin for further information.

Marlon FS Hard is suitable for the following processes:

- Fabrication

- Routering, milling, sawing

- Guillotining, die cutting

- Engraving

- Drilling

- Laminating

- Bonding

- Reverse printing

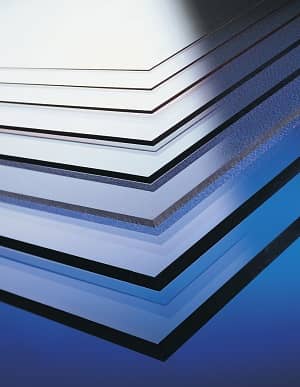

- Marlon FS Hard is a high quality, extruded, solid, flat plastic sheet made of polycarbonate with an abrasion resistant coating.

- As polycarbonate is a thermoplastic, it is important to take thermal expansion and contraction into account during any installation process.

- Marlon FS Hard has been independently tested to various Fire Standards; for the most current certification please contact the Technical Department.

- Marlon FS Hard is REACH and RoHS compliant, and 100% recyclable

- The abrasion resistant properties of Marlon FS Hard are achieved by a dual sided coating. The cut edges are therefore not protected.